What is a High-temperature Resistant Label?

As a self-adhesive product used in a highly harsh high-temperature production environment, the high-temperature resistant label needs to keep the product from warping, falling off, and discoloration for some time in the high-temperature environment to ensure that the information on the label surface is clear. Therefore, there are stringent requirements for the substrate layer, surface coating, and back adhesive layer of the label.

Usually, the high-temperature label is made of polyimide film as the base material and coated with unique pressure-sensitive adhesive. It has good chemical resistance and wears resistance. It has a specific anti-corrosion effect on chemical substances such as flux, melting agent, and cleaner. It can maintain excellent performance when used in an extremely harsh environment of high temperature and wear.

Content:

Material properties

Manufacturing process

Application scenario

Advantages and disadvantages

Material Properties of The High-temperature Label

The structure of a high-temperature resistant label mainly has three parts: substrate, adhesive, and substrate.

1. Substrate

The polyimide film treated with 25um (or 50um) coating can not meet the performance requirements without coating treatment. The coating treatment can better meet the needs of printing bar code and material color and gloss.

2. Adhesive

Now adhesives are generally divided into three categories: rubber, acrylic, and silicone.

Rubber has the advantages of low cost, poor temperature resistance, and chemical resistance, and the outstanding one is poor aging resistance; The performance of silicone is superior, but the remarkable thing is that it is costly; The temperature resistance of acrylic adhesive is about 200 ℃, the chemical resistance and oxidation resistance are also very good, and the price is moderate. 90% of the bonds of some brand tapes are made of acrylic acid.

3. Substrate

Grain release paper, white single copper release paper, silicon yellow release paper, pet release film.

Products are widely used in electronic manufacturing, aluminum, aerospace, and other industries.

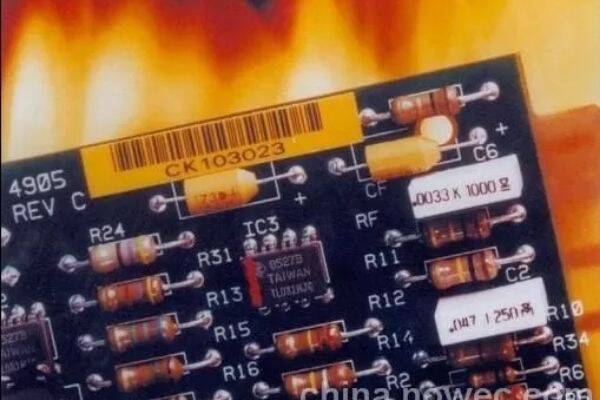

High temperature-resistant labels can resist all kinds of chemical erosion and wear. No matter how bad the process is faced by the brands on circuit boards or components, high temperature-resistant self-adhesive labels can always ensure high perspiration definition and stable readability without falling off and deformation.

The Manufacturing Process of High-temperature-resistant Label

The manufacturing process of the high-temperature title:

Materials: reinforced glass fiber grinding wheel mesh, phenolic resin, reinforced glass fiber.

Process: the product is made of glass fiber mesh coated with phenolic resin, dried and cut

Firstly, the resin grinding wheel is fixed, and the curing operation can be carried out in a fixed curing furnace or a flowing tunnel curing kiln. The position of the grinding wheel is significant for curing in the curing furnace. Generally, the grinding wheel is fixed with a steel or ceramic disc to ensure that the grinding wheel does not deform during curing and is evenly placed in the furnace.

There should be air circulation in the furnace to heat all parts evenly, and then start the temperature rise process for curing; Use a tunnel curing kiln for curing. First, fix the grinding wheel with a steel or ceramic disc, place it in the trolley, push it into the tunnel and run at the set speed. Generally, the initial temperature is 60-80 ℃, and the final temperature is 160-190 ℃. The whole curing process takes 20-25 hours, and finally, the temperature is reduced to 40-60 ℃. Open the furnace door and take out the grinding wheel. Physical and chemical changes occur in the whole heating process, and the following reactions mainly occur in each temperature stage:

1. At 80 ℃, the resin begins to melt, water evaporates, and the curing reaction begins;

2. Decompose six times at 110 ℃ and promote the crosslinking of molten resin, and release ammonia, water, and other gases at the same time;

3. Crosslink the resin at 110-180 ℃ until it is completely cured and is released with a large amount of ammonia.

Too long time in the high-temperature zone will lead to over-curing of the resin, and the strength of the grinding wheel will decrease while the hardness of the grinding wheel increases. Generally, different curing curves and final curing temperatures are selected according to the other requirements of the grinding wheel.

The final temperature is 165-170 ℃, the grinding wheel is complex, the absolute temperature is 175-180 ℃, the grinding wheel is difficult, and the final temperature is 185-190 ℃, the grinding wheel is hard and brittle, which forms a high-temperature label.

Application Scenario of High-temperature-resistant Label

1. Motherboard label

In the electronic industry, it is specially designed for character or bar code labels for printed circuit boards because it can withstand the erosion of welding agents and melting agents in producing printed circuit boards. At present, the thickness is mainly 25um and 50um. The standard colors are black and white. High-temperature resistant label stickers are widely used in SMT and wave crest manufacturing of many electronic products, high-temperature resistant labels of the motherboard, corrosive products, mobile phones, and lithium batteries. Astatine technology GW003 motherboard label is widely used in the electronic industry, perfectly meeting the requirements of high-temperature resistance and welding agent corrosion resistance.

2. Engine label

The automobile engine is the heart of the automobile. Its temperature is very high, and the labeling environment is relatively harsh. The engine label plays a vital role in warning and tracing. Oil stains and high temperatures often accompany the automobile engine. Therefore, the automobile engine label needs super viscosity, good oil stain resistance, and scratch resistance and is not damaged by ambient temperature, humidity, and oil stain. Ensure the integrity of parameters and QR code information. High-temperature resistant engine label is a particular polyimide film (PI), which is formed by condensation polymerization and tape casting of pyromellitic dianhydride (PMDA) and Diaminodiphenyl ether (DDE) in a solid polar solvent, and then amination. It is a yellow transparent high-temperature material with a resistance of 280 ℃ to 320 ℃. Astatine technology GW series engine label has stable performance and clear printing. It is widely used in high-temperature parts such as automobile engines, gearboxes, and compressors.

3. Steel label

The iron and steel industry has the highest requirements for labels, which are mainly related to exceptional environment and performance, and generally up to 200-1000 degrees. Ensuring that the information is readable and easy to retain in a high-temperature environment has always been a complex problem for labels in the iron and steel industry. Astatine Technology is also experimenting and improving. Our products have high-temperature resistance, chemical solvent resistance, oil stain resistance, friction resistance Halogen-free, tensile and tear resistance. Pi / PET/aluminum foil can also be selected according to the high temperature.

Advantages of High-temperature-resistant Label

advantage

1. It has electrical insulation;

2. It has meager stripping force, and die-cutting can be marked automatically;

3. The cost is objectively, and the waste can be discharged automatically

4. High and low-temperature resistance - 40 ℃ - 400 ℃;

5. Bar code printing is clear;

6. Excellent characteristics: waterproof, wear-resistance, and scratch resistance;

7. Excellent development characteristics: chemical corrosion resistance, pollution resistance, chemical reaction solvent resistance, tensile resistance, and tear resistance;

Related Articles

Product Groups

- Metallic Label

- Supermarket Labels

- Food Label

- Tyre Label

- Resealable Label

- Holographic Labels

- Electrical Label

- Adhesive Vinyl Roll

- Inkjet Vinyl Sticker Paper

- Paper Box

- Temperature Resistant Labels

- Clothing Label

- Office Labels

- Bubble Mailer

- Bottle Label

- Chemical Label

- Anti Counterfeit Label

- Temperature Indicator Sticker